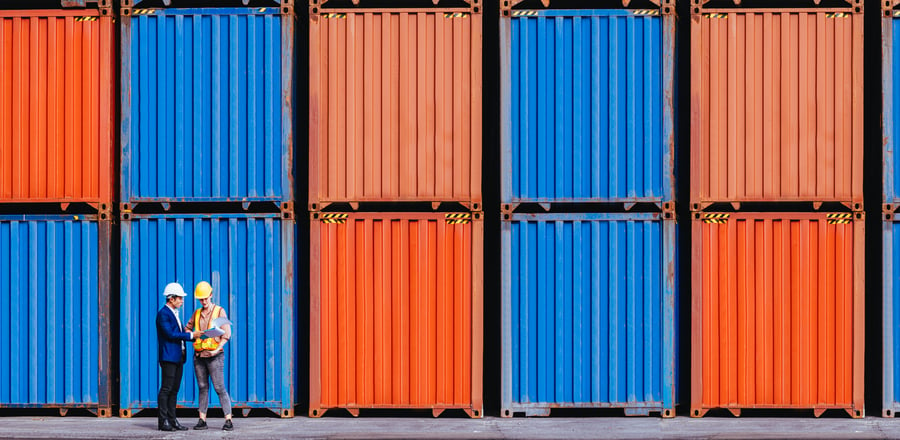

While it’s often cost-effective and more efficient to use international suppliers than domestic ones, questions inevitably come up.

Is it better to partner with fewer suppliers? Will this help us improve the quality of goods delivered? Should we allocate the production of all our goods to a single country? Is it better to diversify production to multiple suppliers across multiple countries?

If you ask us, it’s better to diversify your supply chain across suppliers and countries. This will reduce your risk considerably, as Arthur K. Watson, former president of IBM’s World Trade Corporation, championed during his tenure at the technology giant from the 1940s - 1970s.

A keen traveller, Watson saw the future of IBM outside of the U.S. and made connections with manufacturers and suppliers all over the world. He helped build up economies in Asia and Latin America, forged lasting relationships with the European Economic Community and established computer training camps in Africa. By the time Watson resigned in 1970, IBM’s World Trade Corporation sales had grown to over $2.5 billion and business operations were set up in 108 countries.

IBM has continued Watson’s work, partnering with suppliers in several countries that include India and Brazil. As they haven’t put all their eggs in one basket, IBM has become more resilient against supply chain risk.

The opposite approach is to rely on only a few suppliers and allocate production to a single country. But that’s a sure-fire recipe for increasing supply chain risk.

Let’s put it this way. Imagine if over 50% of your international suppliers are based in one country and there’s a lot of political unrest. This could lead to worker protests, walkouts or a complete factory shutdown – all of which will bring your production to a screeching halt.

But that’s not the only danger. If you don’t do any due diligence on your international suppliers and over 50% of them get into financial trouble and have to shut down their factories, that means those orders (which are likely to account for a significant volume of your sales) can’t be completed. And then you’ll be stuck in a hard place, trying to find other suppliers who can take those orders and hoping they have capacity. If they don’t, you could end up with product shortages, which means your customers won’t get the products they need and want. And that could make them frustrated and more likely to buy from your competitors. Not what you want to happen, right?

There really is so much to consider if you want to de-risk your global supply chain. So, let’s explore some of the dangers associated with supplier over-reliance. The more you know, the better equipped you’ll be.